MAINTENANCE HOW-TO FOR YOUR HARLEY SPORTSTER OR DYNA

Springtime is here and most likely your motorcycle has been sitting in the back corner of your garage, crying to go for a ride. Please don't give into the temptations, just dusting it off thinking everything is hunky dory and go for a ride as soon as you get a glimpse of sunlight!

Take a few hours out of your day and do the oil & fluids change and routine maintenance your bike needs and deserves before hitting the open road.

WATCH VIDEO: SPRINGTIME MAINTENANCE FOR HARLEY SPORTSTER & DYNA HOW-TO

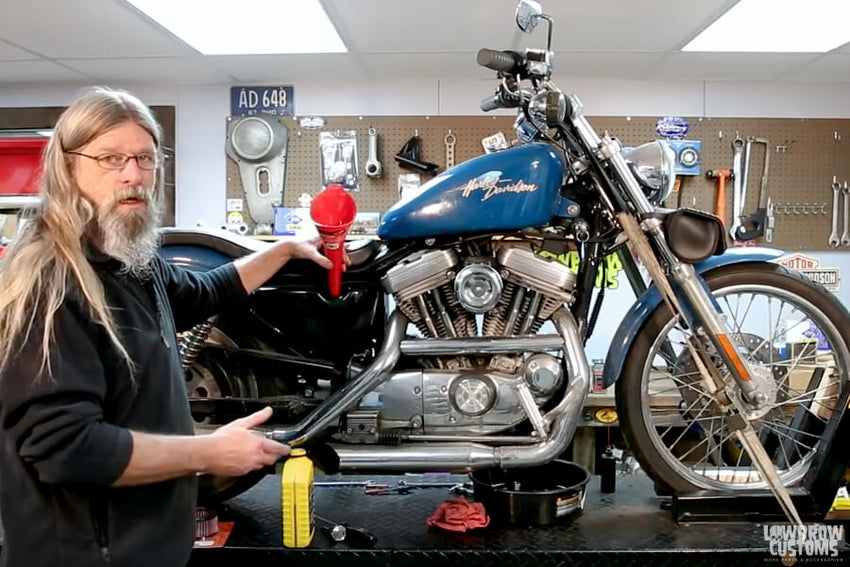

Follow along as Todd walks you through all the basic service your Harley-Davidson Sportster and Dyna need to keep it in tip-top shape. This maintenance will make sure your first ride and many more rides after go safely and smoothly throughout the season.

In our comprehensive video below Todd covers and demonstrates the following maintenance tasks for Sportsters and Dynas:

- Check The Battery

- Engine Oil Change

- Primary Oil Change

- Transmission Oil Change

- Primary Chain Inspection & Adjustment

- Lubrication Of Moving Joints

- Check Tire Pressure

- Belt Drive & Chain Drive Inspection and Adjustment

- Lubricate the Chain

- Check & Clean Air Filter Element

- Lube Throttle Cable / Cables

- Fix A Sticky Throttle

- Check Your Lights

- GO FOR A RIDE!

With these basic routine maintenance tips and a few hours of your time you will have plenty of confidence in your motorcycle whether riding around locally or on a long-distance adventure.

You can read a full transcription of this video below:

Hey, guys. It's your friend, Todd here at Lowbrow Customs, again. Today, what we're going to talk about is we know your bike's been sitting in the shed or the garage or the barn all winter long in the cold. It's getting pretty soon, It's going to be springtime. Okay, I know some places in the country you're already freaking riding around, but we're not. It's been snowing and cold here for months and months and months.

Well, any day now the sun might come out and what we're going to do is we're going to want to take our motorcycle for a ride. Well, before we do so, we want to be safe out there on the road. We want to make sure that our bike is going to be performing correctly not just going off half-cocked. "Oh, the sun's out today let's go for a ride", no, you go out with 10 pounds air in your tire. That ain't cool. What we're going to do now is we're going to do a little safety service check on this fine motorcycle right here.

Okay, the first thing I want to do here is I'm going to go ahead and check the battery. I just got an El Cheapo Auto Parts store meter here. I'm going to set it to DC volts. I'm going to pop the seat off because it's easier to get to the battery terminals here. If the battery's low because it hasn't been on the tender all winter, I'm going to throw the charger on it before we start doing the oil change and checking some other things on the bike. That way it'll be charged up when we're ready to go. Let's pop the seat off here. Meter, DC volts. We want to go, red on the positive. Battery is marked right there on the top, obviously. Ding-ding-ding.

She's showing 12.1. That may be enough to start the bike, but guess what, I'm going to throw the charger on there any way at two amps and give it a little better charge than that because it should be a little higher than that. It won't hurt a darn thing. Got my handy-dandy battery charger here. Obviously, once the bike's put back on the road, the charging system will be charging the battery, but for now, we'll throw this on there while we're working on it on two amps, which would be the same as if you had one of those little battery tender trickle chargers.

Normally, when I'm doing an oil change on a bike, I like to take it outside and fire it up, to warm up the oil, but since I'm not going to start it up here in our studio, I mean my office, I'm just going to go ahead and drain the oil. Let's get that started next because it takes a little time for it to drain. If it is hot and warm, it does drain faster. It's not hot, it's not warm, it'll drain a little slower. On this model, Sportster, Evo Sportster non-rubber mount, there's a hose right here, and it's got a hose clamp. There's a little nubby on this bracket here. That's how you drain the oil. It just plugs on to that nubby so you loosen the hose clamp, pull the hose off, direct it towards our oil pan, and it'll drain out.

Okay, so I've got my hose clamp loose here. Once again, this hose connects up to the bottom of the tank, and you'll see when I pop this off of here and the oil starts draining out this little nubby that I was speaking of. This thing's really greasy. There she goes. See the nub right here. That's all this hose just plugs onto that. Turn that down like so and now the engine oil that's in the oil tank is draining out. It's also helpful to just pop the lid. Take the lid off of the oil tank because it is draining. It will let more air in and also we're going to have to fill it up when it's done draining. We're done with our oil change.

All right, one of the cool things about servicing a Sportster is it's got two fluids, engine oil which is the tank where I just took the lid off, and it's got primary and transmission fluid because the primary and the transmissions share the same fluid. We're only changing two oils. On a big twin, you're going to have three fluids. You're going to have motor oil, transmission fluid and primary fluid, so you have three things to drain. On this one, we only have two things to drain. Well, the cool thing about this is the drain plug for the primary is right underneath there, so I could take that out now and slide my pan over a little bit and do both oils at the same time.

All right, on this drain plug, you can either use a quarter inch Allen because there's Allen up inside there like so or you can use a wrench on the hex. I prefer the Allen. This is it, your drain plug on your primary. Go ahead and loosen that up. This is a magnetic drain plug. There's also an O-ring on here that keeps the oil in the primary. Go ahead and pop that out of there and then the primary will start draining. Like so. Then also notice you got some fur on that magnet right there, see it? Not unusual, nothing to be alarmed about. We're going to clean that off with some brake clean, replace the O-ring. When that gets done draining, we'll put this back in.

Okay, while that oil is draining, I like to take this cover off. Next, this is going to be access to refill it and also we'll be able to check our primary chain adjustment once we take this cover off. There's going to be three O-rings here, one on each screw and one on the cover itself. Allen hood, this is a 5 30 seconds. I like to use a ratchet on this rather than a T-handle, because sometimes if these haven't been out for a while, they can get real tight on you. This works well. There's your first, see there's an O-ring on there. There's no ring on that one. Then, there's an O-ring in this groove on there. The other reason I like taking these off is because then I don't forget that I didn't fill it up. If the cover's off, it's empty, in my opinion.

Okay, now, you can see our primary chain here. You can see your primary chain right there in the hole, towards the top of the hole. Checking tension. You're just going to, you want it to go up about that adjustment looks very good there. Now, if it was too loose, if you put your finger in there and it's slopping all around in there, if you did need to adjust it, we'll show you how that's done. It's very simple adjustment on this particular model.

In order to adjust the tension on this chain, on the bottom of the primary, you've got this lock nut and this stud. That is attached to a shoe inside here and so very simple to adjust. If you do need to adjust it, we'll just go ahead and loosen up and show you how it's done. You're going to loosen the nut enough that you could turn the center. See how the nut's loosening but the stud part is just staying still. Then, there's an Allen in the center of this, see?

Then, to tension the chain, if you look right here, see the chain moving up, see the chain moving down. That's simply moving it up or down to tension it. That's back where we started. See it moving through the chain? That's moving the shoe at the bottom and putting more tension on the chain. If it's too loose, you want to tension it up, you want a little bit of a play in there, the specification for that can be found in your workshop manual. You do have a workshop manual, don't you? Well, if you don't we have some manuals for dyna available on the website.

Then, when you go and when you get your tension set correctly, you're going to retighten that nut while holding the Allen wrench in the bottom so that the setting doesn't get changed. Because sometimes you'll find that when you're tightening this the stud will move along with it. Then, when you go to check it again, you'll go, "Oh, gee. That's too tight." There we go. Pretty simple basic stuff there adjusting your primary chain, no big deal. Well, my oil is just about done draining. Next thing we'll do after those are done is we'll put the hose back on and we'll put the plug back in the primary. Then, we'll slide our pan up to the filter.

Let's talk about filters for a second. It's always important that you get the right filter for your model. You don't want to put a twin-cam, big twin filter on your Evo Sportster, because the microns are different. There's a little pressure disc in there and those are different, so make sure you're using the right oil filter. Also, we'll talk about oil filter wrenches really quick. This happens to be a K&N filter and that's what we're going to be using because that's what we have on the website. We have these and we have some S&S filters.

This particular filter from K&N which we have on the website. It has a hex head where you can just use a socket to take it on and off which is cool. I have a stocked Harley filter here. That one has this flat spots around the outside edge of it. That takes like a regular oil filter wrench. Well, this is something I bought it. Kmart Vector brand, made in US. The reason you're seeing this weird thing on here is because on some of the big twins you can't get the filter on there. Well, obviously that's not working on the K&N, but if you have a stock Harley you can pick one of these up on this model you don't need to modify it like I've done on a big twin. Some of the big twins you do have to make that little window there but that just fits on like so and that's to spin your filter off.

Now if you get a very troublesome filter that does not want to come off. It's stuck on there and no matter how it spins the wrench there's also this style filter wrench. What some guys will do is they'll take a screwdriver and jab it in their pry it off. This little honey right here works real well for the very stuck filter that doesn't want to come off. That's called a strap wrench also works on a variety of sizes of filters because look how large it is now.

You're just going to wrap it around the filter and then you're going to twist it until it comes down and obviously you're wrapping it the direction and then you're going to throw a half inch wrench and or ratchet in there and see how it just spins it right off. Piece of cake. If you get a real stubborn one this is another tool. This is KD brand US not very expensive. Whatever works for you, you got to get that filter off of there.

On my primary drain plugs pretty greasy and oily and covered with fur metal shaving. We're just going to give it a quick wipe and we're going to give it a blast, a little bit of brake clean. Look at that, look how that makes it all nice and shiny and clean again. We still got a little bit of metal on there you want to get all that junk off there, all that fur, then like I said there's an O-ring here.

It's not imperative that you change these O-rings every single time but I just noticed this one's starting to get shaved from being tightened and taken off a couple times. I do have some new O-rings here. This is the one that's going to go on here and then I have the larger one that goes here and then I have the two small ones that go on the screws. Let's go ahead and pop this off here just you can use a pack or knife, whatever you got handy to get that sucker off of there like so. See there's a little groove on here where that O-ring rides. We'll go ahead and just pop the new one on.

First step we'll put the primary drain plug in, we'll plug in that hose and then we'll be ready to fill up our new fluids. We got the drain plug in and tight pop the hose back on the little nubby there. As soon as you get that hose back on the nubby grab your screwdriver and tighten down the room drive hose clamp because it's doubtful it's going to pop off the nubby. If it did, it would probably spray oil all over your back tire and then you slide your bike sideways crash into a guardrail and die. We don't want that to happen make sure you tighten your hose clamp.

Now that we got the drain plug in and the hose back on, we'll just go ahead and slide the pan right up under the filter and get that taken off now cause a bunch of oil is going to go everywhere. Watch this, Harley really did a good job designing their oil filter locations on some of these models. This one is pretty much the same as the other ones. There she goes look at her, she's a gusher all over everywhere. Now before you put the new filter back on I usually take a rag and clean that old oil off of there. We're going to grab a quarter of this PanAm 20-50 motor oil available on lowbrowcustoms.com. Good stuff put it in your bike, use it.

Before we put the filter back on we're going to dump some in the middle. Whoa, hey, like that. That may have been a little bit too much but that's okay we're going to get some fresh oil on the new gasket. Put the new filter on. Don't want to over tighten your oil filter. Basically here's a reference point is this little hole in that stud there you want to turn it probably like half a turn three quarter of a turn after it's contacted. Since it's becoming hard already, now we have some place to put that we'll just put a wrench on there and we're just going to suck it up. We're not going to crank it on there doesn't need to be cranked on there. That's probably good right there.

Now to get rid of that extra oil that went everywhere you can use a little brake clean. Spread that around there, get it around there, get it everywhere. If you don't do that as soon as you start riding down the road and you park your bike somewhere somebody's going to think you have an oil leak because oil is going to be dripping everywhere. We don't want that happening, clean her off real good. You can also use a little compressed air after you put your brake clean on there, clean that up, get her done.

While we're still on this side of the bike we'll go ahead and fill up the primary and put our new O-rings on the cover. We'll just give that a quick cleanup here she's pretty grungy. I'll clean that up, we got a new O-ring for that. We'll take these two small O-rings off the cover screws, get some new ones on there because we don't want our motorcycle to leak oil. We got some transmission primary oil PanAm brand capacity one quart you can just dump the whole thing in there be done with it. With this handy dandy funnel fits in there we go.

That's a slow-moving funnel their gang she just got a little hole on the other end and a big hole on this side. I don't know what's up with that and this is specifically for Sportster see it says right there on the label for Sportsters. There she goes, look at her, look at her go, there we go. Give her a little rub down there. Hey look at that added bonus, we got a little oil on the shifter linkage that's always good. New gasket notice the cover it's thick, it's thin, thick, thin. Whoa look out you want to put it on there like so with the thick portion on the bottom and our two screws, once again don't overdo it. That's it we're done with the primary.

Let's get the oil filled up here once again with our slow-moving funnel here. It is worth mentioning this is a 3-quart system. I can pretty much guarantee you, we're not going to put three whole quarts of oil in here. One of the biggest problems I used to see at the shop on a regular basis is Sportsters and Softails with overfilled oil tanks. Just because it says a whole 3-quarts doesn't mean 3-quarts are going to fit in there and what will happen is, there's a internal breather in there. If you cover up that breather with oil now it's looking for the path of least resistance which just happens to be your top end breather.

If you see that you have excessive oil coming out of your top end breather, first thing you can check is your oil level. You don't want to overfill these babies. I'm going to put two quarts in and then I'm going to grab my trusty flashlight and I'm going to look down the hole, I'm going to see where the level is. We got two quarts in there let's have a look and see where it's at. She's getting up there pretty close, let's just add a little bit more and it's much easier to add more than it is to take some away.

Now you'll notice on your dipstick on this model. There's two rings machined into the dipstick. This is the add mark, this is the full mark. After an oil change you should be somewhere near that full mark and once you're using the motorcycle and if you check your oil on a regular basis, which really shouldn't be necessary. If you happen to check it as long as it's in between those two marks you're safe. If it falls below that mark there that means it's time to add some. There we are, we're above the add mark and we'll put just a little bit more in.

Then the other thing we're going to need to do is we're going to need to for the final oil level, we're going to need to start the engine and run it for a few minutes to fill up the filter and then double check the level one final time. Out of three quarts of oil looks like we're at about two and a half right now. That should be good we'll just take one last look where it's at on the stick now. See, now we're almost halfway up the stick, that'll be good to run it.

If you're doing your spring service on a big twin model we're going to have three fluids to change instead of two versus a Sportster where we only have once again the clutch and transmission share the same oil. On a big twin you have primary fluid, engine oil and transmission fluid, you have three fluids to change here. Once again we're going to be using PanAm oils on this. This is for the primary oil and this one is for the transmission. Once again 2050 PanAm for the engine.

Drain plugs on this one. They're going to take the same quarter inch allen socket or once again you can use a wrench. Now there's something important on this where the oil pan is on the bottom of the transmission and basically there's going to be we'll look here in a sec. There's one plug that faces this way out like right about under here and that's going to be the oil drain. Then on the other side of the bike there's a plug that faces down that's going to be the transmission. Then the primary is going to be very similar to the sportster it's going to be on the on the bottom of the primary on this inner primary cover where we're going to drain the tranny.

In order to refill the primary we're going to be removing this derby cover because this is an 08 and they had removed the inspection cover here. Your bike if it's an earlier model, if it's an EVO or an earlier Twin Cam you're going to have an inspection cover here where you can fill up the primary and also check your chain tension. This bike has an automatic chain tensioner we don't need to check the primary chain on it which was a feature they did in later model, one less thing to do for your maintenance. We still have to remove this cover in order to fill it because Harley wasn't smart enough to put a hole or something to fill it up once you drain it. We'll show that in a sec here.

Let's go ahead and remove the drain plugs and get her draining might be hard to see back up underneath here, but the one that's facing down right there on the right hand side of the bike is going to be the transmission drain. This is going to be the oil drain and this is going to be the primary drain. One of the positive things about all three of those plugs being very close proximity to each other is we may be able to get away with taking all three of them out at the same time. Let's give it a shot see what happens here.

We'll start with the transmission because it's further away and we don't want to get oil on us. Motor oil will be dripping out and it's hard to have your wrench on there and draw a pan under there at the same time. We're going to run her down until she's just about coming out, actually we go like this, we got it. I just took the socket off the ratchet and I'm unscrewing it and guaranteed to get some on your hand if you don't get any on your hand, you're probably not doing it right.

There we go, transmission is draining same program as a Sportster. We've got magnetic drain plugs with O-rings. Now you may have noticed how the oil one is facing this way, it's going to want to gush out. We're going to slide our pan over when that one almost comes out. There the tranny still draining into the pan and then we're going to pop the oil one out. Once again you don't get it on your hand, you're probably not holding your mouth right, there we go. You may notice now it's not draining very quickly out of the oil probably if we go pull the dipstick out, it'll start coming out a lot faster.

This model has a threaded dipstick, yours may have a push fit. Would you look at that taking the dipstick out made it flow much better. You still got to pop the primary one off and it's not gushing too much, we'll move that over. There we go, all three fluids are now draining at the same time. Now while we're waiting for that drain, we'll go ahead and pop this cover off because that's once again, that's how we're going to fill it up and we're going to need to T-27 for that.

When you're taking the last screw out it's good to support the cover so it doesn't fall on the floor cause sometimes they're stuck on there and sometimes they're not. There we go there's our cover off and look Harley-Davidson put a little slot right there, you can stick at the tiniest of funnel in there to refill it wasn't that thoughtful of them. We went ahead and cleaned all the magnetic drain plugs and put some new O-rings on there. Now I'll go ahead and looks like we're done draining we'll go ahead and get this out of the way and put our drain plugs back in.

Now we've got three steel drain plugs and three aluminum holes, we don't want to over tighten them. We want them to seal, but we don't want to rip the threads out of the covers or the oil pan and this inner cover here. Tight but not too tight. We'll go ahead and slide our pan up to our oil filter area. Once again, Harley put the oil filter in a really nice place where it leaks everywhere when you take it off. We'll go ahead and show you the purpose of this. Look at that, that's a stock filter. We want to prime up our oil filter by adding some before installing that should be good. Once again, a little bit of oil on the ceiling gasket like so. Install your filter.

Once again when the gasket contacts the surface you want to turn it about a half turn or so, quarter to half turn. That should be good. Now we can go ahead and fill up our fluid levels, go ahead and fill up the primary. Notice how the PanAm oils have color coding on them which is nice and here's the funnel in that little tiny slot they provided for us drain plugs in and tight. Capacity is going to be one quart, we're going to put the whole thing in here. This is a aftermarket primary cover we're not going to need to change the gasket it looks pretty good to me wasn't leaking before.

When we have them all in we're going to go ahead and tighten them up and we're going to do it in a cross pattern. We're not just going to go around in a circle and tighten them. I don't think there's much chance of this cover being distorted because it's so dam thick. This is a great way to tighten them up, ensure there's an inch pound torque spec on here but I'm not really going to pull out an inch pound torque wrench just the torque these little tiny screws. I got them all ran down, I'm just going to give it that extra little. Capacity on this model is three quarts and this one's going to need to be checked on the jiffy stand if you're unsure as to what position your bike should be in for checking your oil consult your service manual.

Some of them are straight up and down and some are on the jiffy stand. All right once again same deal as a Sportster just because this is a 3 quart system doesn't mean we're going to put all three in right at the same time all at once. Well let's take a look at our dipstick real quick here just for the heck of it. On the backside of it it does reinforce what I'm telling you check on jiffy stand.

On the other side there's some marks here says there's a full hot and an add oil. Well like I just got done saying we're going to go ahead and warm the bike up before we do our final oil level check. When I was working at the shop I would basically put two and a half, two and three-quarter quarts in. I put my stick back in I'd take my bike for a test ride to double-check all the things I've done on the service make sure everything's working well. Then when I'd get back to the shop before I'd send the bike down to the wash bay to be cleaned up for the customer, I would pull the dipstick out one last time and verify my level is correct at the full hot mark.

There's also an add mark here. If you're down there that's bad if you're up in this range, you don't have to be exactly at the full hot you want to be up towards that portion right there and you're fine. We're going to go ahead and fill up the transmission fluid, this model takes one quart and as usual Harley put it in a real good place to get to. We'll hope for the best here, put our transmission dipstick back in and tighten her down. That's it all three fluids are filter changed on our Dyna. We also have another job on this side of the motorcycle.

We're going put some new spark plugs in her, a little bit around on there, when we start loosening the plugs that oil go down in the threads. Factory service interval says to change your spark plugs every 10,000 miles. Well, we used to have bikes coming in for 5,000 mile service and it said to inspect the plugs, I just put a new set in. These bikes like new spark plugs and they're not very costly. hen if you don't change them and you get one fouled out on the road then you got to ride her home on one cylinder, that's no fun, it sounds funny too.

Anytime you're putting new spark plugs in you want to verify that you have a gap. You can also check the spec of the book if you're so inclined. Got my official EX service manual here and I marked the page earlier in the day here so we wouldn't have to be looking around for it but it is in the index under spark plugs. It says right here the gap on the spark plugs for this model should be .038 to .043. All right so once you've verified your gap with a wire gauge any time you're putting new plugs in little dab anti-seize on the threads like so. Don't get it on the electrode that's not good for the plug.

Anti-seize on there helps it go in, helps it come out next time you're ready to change the plugs. Once again no over tightening of spark plug. Make sure your plug wires are clicked on like so, beautiful thing. All right a couple of one other things not a bad idea grab yourself a can of WD, any of these moving parts here, stuff like this, choke cable, give yourself some lubrication there. Everybody likes a little Lube on her, all right. I have one other thing I want to do on this side of the bike here, I'm going to give you a little break service tech tip here along with our service and as you're checking things over or you want to take a look at your brake pads, you want to make sure these are going to be good for the season.

If they're starting to get worn down and there's nothing left on them then maybe get yourself a set ordered up. If you got them a mushy lever, what I would do on a lot of services is I would take the caliper off and clean the disk with some brake clean and also clean the caliper, you get brake dust in there. A little bit of brake clean some, compressed air and basically I'd pump the brakes pump the handle with the caliper off and make the pistons come out, clean all the brake dust off of there and put it all back together and wow, magically without even changing the fluid, checking the fluid, adding fluid, lever feels beautiful.

For you guys can get a good look at what the brake pads look like on here, we're going just pop this off because generally. If you're not taking it off or doing all that other stuff I just talked about, you can take your flashlight and shine it down and look at the condition of the two pads. For your viewing pleasure, we're going to just pop this baby off here and you can see those pads look pretty good, they're not too bad. The inside one is getting a little thin, a little bit thinner than the other one but it's not terrible. Those should be okay for a few more miles. Let's break clean, take your air, not as bad as some of the ones I've done in the past and that looks pretty good.

We'll put her back together. If you do find that your pads run down they're very close to nothing or if you-- I've seen this on a lot of baggers where they have saddle bags and whatnot on the back and people don't pay attention to their brakes and they run them down to nothingness and then you start getting some grooves on your disk. Well, there is a minimum thickness right here on your disk can be measured with a micrometer or caliper and if your disks are worn beyond their useful life, it's probably a good idea to put some new ones on there.

Be sure to retort these with your torque wrench they do have a torque spec. We checked the front brake pads, we'll go ahead and check the rear, oh boy. That one outside these brakes are just about shot. I'm going to have to tell my coworker long hair. Oh wait I got long hair well that's his nickname even though I got long hair he's got long hair too. I ought to tell him we need to get a set of brake pads for this bike here because the rear ones are pretty much almost done. They're not going to last through another season that's for darn sure.

Well I went ahead and disconnected the battery charger, we'll just give the battery quick final inspection here. Oh yes baby, look at that, 12 8, that's way better than it was before I put the two amps on there. Once again make sure your batteries up to snuff, it also doesn't hurt to grab your 10 millimeter battery wrench and just to check your cables and make sure they're tight. Because if they're not tight you could have a charging problem, okay there's no doubt in my mind that as your bike sits over the winter time you're going definitely need to check your tire pressure.

If you don't do any of these other things before you go for your first ride please put some air in your tires okay? 21 inch front, I prefer to have at least 36 pounds in that 21 inch front tire and I'll tell you why. When I used to work at the shop I don't know how many bent 21 inch rims I saw in the many years of changing tire after tire after tire after tire. Put a new tire on throw it on spin balancer, call Joe Smith, this rim's bent. He didn't even know it because he was riding around with 10 pounds air in the tire. 36 to 40 is a good number for a 21 in my book.

There we go, perfect on the money, 30 pounds, you think that's enough? I guess if you're a hardtail. Sitting a

Related Products