Learn How To Tune Up & Maintain Your Harley-Davidson Ironhead Sportster

- Changing Oil & Fluids

- Adjusting the Valve Train

- Ignition Maintenance

- Ignition Timing

- Fuel System

- Electrical

- & More!

WATCH THE FULL LENGTH IRONHEAD SPORTSTER TUNE & SERVICE VIDEO

Follow Frank's tips and tricks and you'll build the skills you need to resurrect that old project and keep your bike running strong with confidence! You can also own your own copy of the Ironhead Tune & Service DVD for only $9.95!

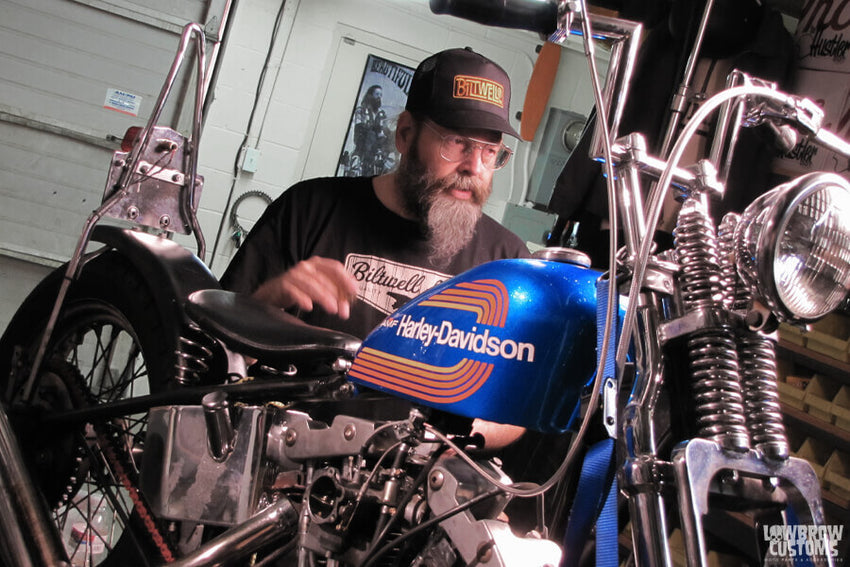

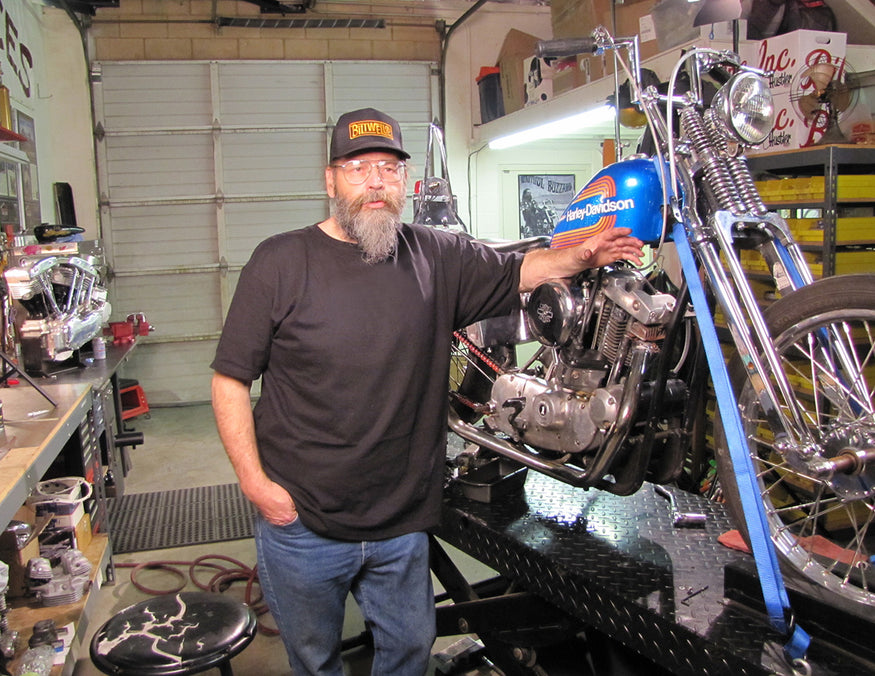

This Harley Ironhead Sportster chopper was a good candidate for some tune and service work for this how-to video. Though it has many custom Sportster parts, the work performed on it is the same as on a stock motorcycle.

Frank Kaisler has been immersed in Harley-Davidson motorcycles for more than 50 years. He bought his first motorcycle, a Panhead, at age 12. Frank was also editor of Easyriders for a while in the 1970s.

Ironhead Sportster Tune & Service Video Full Transcription:

Frank Kaisler: Hello my name is Frank Kaisler, Wes and Tyler asked me to help illustrate this DVD by demonstrating the proper way to do certain aspects of maintenance on your Harley-Davidson motorcycle. I've been riding custom-Harley motorcycles for over 40 years. I've been involved in their custom motorcycle magazine business for about 30-some years. Starting with Easyriders magazine. I've worked in custom motorcycle shops, I've worked in Harley-Davidson dealerships, I've worked in my own garage, I've had my own shop.

A lot of what we're going to pass on to you today has been gleaned from years and years of making mistakes. You make a mistake, you learn the right way to do it. That's all we're going to show you, is the right way here. You can take it for what it's worth, you can follow what we ask or tell you or you can't, but we know that what we are going to show you works.

We've proven it to ourselves, we've proven it to other people, we've proven it to customers over the years. It's not just going to be the last word. There's always going to be someone who has a different way to do it, to arrive at the same end results. We're going to show you what works for us. I hope you enjoy it and I hope you have a safe riding afterward, thank you

Okay, what we have here is a Ironhead Sportster in a custom frame, that we're going to do some basic maintenance on. First thing you do is we're going to pull the plugs. Before we pull the plugs, we have to clean around them. Easiest way to do that, just take some compressed air, blow any dirt around the plugs before you remove it, so that it doesn't fall in the hole.

The root plug wires, you give a little twist as you pull. Like that, like that. Take them out of the way, plug wrench.

The reason we're going to pull the plugs first is because when we go to adjust the valves and the timing, we're going to have to rotate the engine. It's much easier to rotate the engine when there's no compression in the cylinders. This plug is a little bit dirty. Black, that means it was a little bit of oil-fouled and a little bit gas fouled. Both plugs are out. This one s a little better than the front one. Easy way to rotate the engine is with the kick-starter or by rotating the rear wheel.

Rotate the rear wheel, we just jerk it up. We have a little jack we bought from the auto parts store, it's a used Toyota jack. We made a little flat on it and welded another one. You just use a ratchet or a wrench, raise the rear wheel enough so it spins like that. We'll put it in gear and we like to go to fourth gear because that's the easiest ratio to push. I can see the pistons coming up and down the cylinder so we're good. All right, now we're going to move to the other side and go ahead and adjust the valves first.

Okay, we're going to adjust the valves-- Actually adjust the lifters, then we open pushrods. To do that, we're going to get rid of some of this stuff that's in the way, to make it easier on ourselves because we want to pull the carburetor and the ignition, the magneto, later on. Air cleaner is pretty simple, it has one screw that holds the cover, and one to the backing plate. It'll just come off like this.

Air cleaner is inside, we'll deal with that. Easy way to test that is hold up to the light, if you can see the light through it's pretty good. That was not so bad, the back

See how that opens up everything, so we can see better and get our fat little fingers in there? There's also the magneto that's in the way, so we're going to remove that and we're going to take the cap off first, so it makes it easier to see where the rotor is. When we go to reinstall the mag, which is very easy, we'll rotate the engine around until we get the timing mark in the time and hole where it's supposed to be for this year and model and then we'll just put the mag back in and tighten it up.

Very easy. A lot of people think it's intimidating but it's not. Cap comes right off, no problem. Here's your two contacts for your two springs for the coil. That's what's nice about mag, it's a self-contained ignition system. This is a brand new one. All right, next thing is to get the mag out, so we're going to take this adapter underneath here, there are two bolts that hold it in place.

When we're ready take the mag off the base, you'll see there's a nut and a washer that'll probably fall off when we pull this up like that and it comes out like that and that's what it looks like underneath. It's a Fairbanks-Morse style body but it's driven by this hex, the piece of steel. The hex goes down and is driven off the front intake camshaft. I'll just set that aside. We got all that stuff out of the way so we can adjust the valves. These are custom pushrod tubes, they actually thread together to extend up so they seal, the head with rocker box to the engine cases.

What we did, is we unthreaded those so we could collapse them. You can see how the pushrod tubes move up and down. When I let go of them, gravity takes over and the pushrod tube comes down and gets in a way of your adjustment. In the past, we've used a couple of different devices to hold the pushrod tubes up out of the way.

This is the cheapest and cheerful throttle return spring you can get from an auto parts shop like AutoZone or someplace and you would raise your pushrod tube up, catch it on the bottom and then hook it on to your rocker box like so. There you can see that your pushrod adjustment is exposed. No problem, easy to get to or a couple of years ago a friend of ours who we forgot his name, that's how good a friend he was, gave us this apparatus which is basically a couple of hooks with some cable and you can actually hook both pushrod tubes at the same time so you can adjust both of them simultaneously.

One there, one here. Come on, and then hook it onto the rocker box. There we are. Now we get to both of them. Now we're going to rotate around like we started before. See the intake pushrod just went down which means you're coming up on your compression stroke. When you keep bumping it and you see that it's not moving that means it's on the heal the cam.

The piston is up during compression, so now you want to reach in here and turn the pushrod with your finger. This is very loose, it turns very easy but what you want to do is check for up and downplay which this has a little bit. Which we would require that you adjust it. To adjust them, it has a locknut at the bottom which is a 7/16 inch hex and you have the adjuster on the top of the lifter which is half-inch, so you would hold the top of the adjuster and just loosen a little bit the locknut.

You don't want to loosen it all the way unless you have to collapse the lifter down and take the pushrod out. Once you just loosen a little bit you elongate the lifter, turn it upwards to tighten the clearance. You just have to go a little bit when you're adjusting. Takes a little effort between two fingers to turn the pushrod which is good because this top-end is going to grow when the engine reaches operating temperature and you don't want the pushrod to be too short. You got it where you think it's right, you come back in and you hold the adjuster and tighten the locknut then you come back and check it once again, fine.

All right the final test when you think you got them adjusted, is you come back, you turn the rear wheel again, and completely rotate the engine. There goes, the intake pushrod up, it comes down, and as it comes down, you stick your fingers in here and try and rotate it. Okay, that's fine. Up there it's a little on the loose side so you didn't have it all the way down and this is just a matter of practice. Sometimes you get lucky and it happens right away, sometimes you don't.

When you only have a little bit to go, I always just hold the locknut in place and you could take the adjuster and just give it a little movement. Double-check your pushrod again, spin it around. There it goes up. Come down and it's perfect. Okay, that one is done. Now we're going to watch the front exhaust pushrod. There it goes up, he it comes down and stick your fingers in there. That one is just a little bit on a tight side. Which means we can't move it with our fingers.

Hold the locknut and see if we can just bump it down with the adjuster a skosh. Reaching it, yes that feels good. We'll do the same thing. Rotate it around one more time. Here it comes down, stick your fingers in there. Okay, your finger is a little bit oily so you want to wipe them off, get a good grip on it. Perfect, okay that one's done. Then we'll move to the back, so we just take our little cables off, so come on to the back pushrods and repeat the process.

It's not that difficult, you just want to be conscious that you won't get them the first time unless you're super lucky which we aren't. That's why we like to check them after a couple of engine rotations. Just to make sure we have it the way it should be. All right, we're going to look for the rear intake to go down. Here it goes up, coming down, everything is on compression and that one's a little loose.

Actually, that's got a little bit up and down play, which we don't like. Hold the locknut and turn the adjuster and you only want to go like maybe not even a sixteenth of a turn. Just enough to take a little grip and there we are. That's nice. It should be a little bit of resistance like if you took a pencil or something and you held it on one hand and you tried to turn it with your other fingers. It's going to move but you just want to have a little bit of resistance.

Okay, we're back to checking, going down. As soon as it starts to go down, that's when you want to check it. Right there, that's good. See, it just loosened up a little bit right there. One more little bump right like that, nice.

Perfect. All right, one to do, coming up, going down. That one is a little on the tight side. It wasn't reaching out? That's good, but is it good all the way? Here we go

Perfect and what I take is 15-20 minutes. It's easy to do and the only time you really have to do it, if you can hear your valves clatter or click a little bit because they're solid lifters. There's no hydraulics in it and it's easy to do. Okay, all we have to do now after the pushrod adjustment is put the pushrods back in place. What we've done is we've taken the pushrods in each individual circumstances and take all the slop out and make them adjusted perfectly.

To do that we extended it or collapsed the lifter to the final adjustment and then we rotate the engine to at least two or three times checking the tension as we go. It takes another tough couple of minutes it's easy to do and you're here working with your motorcycle, it can't be that bad. The other thing is when we get the pushrods back up you want to make sure that they're tight and they're sealed, and the only way you find out is once you start it.

Then you want to take this off. When I have the motor like this where the pushrod tubes are loose, you turn them a couple of times you just see black soot and stuff from road grime and whatnot, I always like to clean them while I have them so that I can get to the whole circumference. You just wipe them down, you look down here in the tappet block, there should be a cork gasket that should be intact, these are. Up here in the rocker box, there's a cork gasket that seals the top of the pushrod tube. Stock pushrod tubes have another cork in the middle. These have O-rings since these are customs.

The next item to attend to is a primary chain adjustment, primary chain hooks engine to the transmission. You adjust it on a Sportster by checking it through this access hole. You undo the plug, and you can stick your finger in and reach the chain. The chain should have about a half-inch up and down play, maybe 5/8. This is a little bit excessive, but you always want to adjust your primary chain at the tightest spot.

To do that we pull the plugs back out, we put the bike back in fourth gear, we're going to rotate the rear wheel and rotate it a few degrees coming here and check the tension. There's a tight spot there, and loosened up considerably. That's all right.

Okay, there we are. That's got about maybe three-quarters of an inch play. Which is not much, but it's still more than the factory specifies. To adjust the primary chain on this model, Sportster, which is covered in your sportster service manual, there is a bolt and a nut here at the bottom.

To create more tension, you would turn this shaft in here. You got to loosen that first. You would turn this and check. Turn it, this slot's ground away on this so it's going to be a little bit more difficult but there we go. Can you see that all right?

Adjust a little bit and check, adjust a little bit and check. It feels good right now. We got a real snug but we're going to run it around again, make sure we have it at the tightest spot.

Okay, there's a real loose spot but that's good. That's good. That's good. All right, all we need is probably new primary chain probably next year or so. When you get a loose spot like that. It's not bad as long as you got predominantly a tensioned chain.

Too tight and you're actually going to pull the transmission main shift, and it will start to wear out the bearing. Which also affects the clutch operation since the clutch plates move in and out of the clutch drum. You start putting tension on it by a too tighter primary chain, you're going to make the clutch plate cork which makes the clutch wore. No problem because we got ours adjusted properly.

I'm going to go back here and double-check that we have this tight. Okay, that's fine. Since we can't drain the primary crankcase and transmission on this model, mainly because this is a custom frame, the drain plug is directly over the frame rail. We would go ahead and pull the primary cover off. Tip the bike over on its kickstand and let the oil just drain out into a pan.

Put everything back together. We will pour oil. The proper Sportster chaincase and transmission lubricant in here until-- We took this screw out, there would be a hole. When the oil starts to come out of that hole with a bike upright you’re at the proper level. We will put the screw back in, tighten it up and then go back and put our access plug back in and we'd be done.

This model has a custom oil tank. We have a stock oil tank to show you how that works, but basically, all oil tanks on all Sportsters have three oil lines. You have a feed line from your tank to your oil pump which provides fresh motor oil to the engine. You have another oil line coming off the pump that returns excess oil back to the tank. Then you have a vent line, as your pistons go up and down, it creates pressure at the combustion chamber which makes power but as the pistons come down it also creates pressure in the lower end which has to be vented to the atmosphere or to the oil tank.

The oil feed is always at the bottom or lowest part of the tank where your drain plug is. The two lines we have coming up here. The front line, the highest line should always be your vent, so oil can't get back into your event, back to the motor and swamp the motor. The line right next to it is your return, you always want that at the highest point so you're not pushing oil through oil. The oil would come back from the engine drop down on top of the oil level, the oil level goes down from the engine running. It's a constant reverse process but you don't want the oil level too high because you have no room to vent and you have no room for oil return, no problem.

We will look down here when we move around. Whoever set this up, set up the oil drain or old feed pretty weird. It's got a heavy kink in it which you don't want. Right next to it, and we stick our finger on, is the drain plug. We move around to the other side of the bike and attack the drain plug. Anytime you do a service you should change the oil. Oil is cheap insurance about it giving a good clean long-living motor. Here we have a custom oil tank, custom oil lines. There're three oil lines. There're always three oil lines; feed, return and vent.

We're going to go ahead and drain the oil which is via, usually, the lowest part on the oil tank, so you get all the chuck out of it. This has got an Allen bolt drain plug that has been damaged from the chain flopping around. You can't get an Allen wrench in it, so we're going to have to revert to channel lock pliers to remove. Which work quite effectively. Not as effective though. My fingers are not cooperating. We have a handy drain pan in close proximity to where we think the oil is going to flow out. Geez, you going to need somebody to get this out of here.

This is all part of the fun working on custom motorcycles. Especially new ones you just got. You can actually see there how the chain has worn away the bolt, so you can't get that proper hex key in there.

Wes: We've got some oil in there?

Frank: There's some. There we go, not much. We're going to catch it? Yes. The first thing I look at when I pull the drain plug out of a motorcycles oil tank is the top and you feel for any kind of metal debris or you look for any kind of-- This has got a little bit. A couple of little particles.

This is a cut-off Allen bolt, so this is not the proper drain plug. Most drain plugs will have a small magnet in there to attract any kind of metal or debris that the engine, as it wears in would put back in the oil, and the oil will carry it back to the tank. The filter usually would trap all of this. This motorcycle does not have a filter. All stock bikes would have a filter. This being custom, it's got no filter. That's one of the reasons that you would want to change your oil more frequently. Like every thousand miles, every 1500 miles. Rather than 2500 or 3000. Normally associated with an oil change from a factory motorcycle.

We'll let that drain a little bit. I'm going to turn around and get off the bench our stock oil tank. This is basically a stock tank for each model. Meaning electric start Sportster. It has mounting tabs, all rubber isolated. This would mount to the back of the battery box, here would be your feed from your oil tank to your engine to feed fresh oil. This would be your return from the engine back to the oil tank. This is your vent line. This is your oil fill cap which also houses the oil filter.

You would undo the wing nut, rotate it around and pull it off. There's no filter in there now but we have just purchased a brand new filter from Custom Chrome. Which is a canister style. To install it you would just drop it in, put your cap back on till it stops and tighten it down, as simple as that. Very cheap easy to use insurance to keep your oil nice and clean. The original factory one had a canister where you would put a fiber element down inside the canister and put the canister back in. These are great. You just take it out, throw it away, put a new one in, you're rocking and rolling. This is a nice pleated paper element that traps I think down to 10 microns. I think it does it.

No problem, it doesn't look nearly as nice as a custom chrome or a chrome one with a custom application but this custom one is not rubber-mounted, it doesn't have your battery hold-down and no oil filter provision. There are aftermarket oil filter provisions you could have that you would bolt up somewhere on a motorcycle and run separate oil lines from the engine back to the tank. Not that hard to do, is just the one person who built this bike decide not to go that route.

If you bought something like this and you're more worried about your engine longevity I would recommend putting an oil filter in place. I've done that much. There's plenty of room here behind the seat post they call it, or the frame that you could hide an oil filter there, it's close to the tank you could run short lines up, it'd be good to go. You'll notice on this model it's got braided steel oil lines that run all over the place. Which is not good because braided steel eats other steel. If it lays on there and vibrates it can eat through an exhaust system in a couple of months.

Here we have it laying on the frame rail which already made a little bit of indentation and it just runs haphazardly. It's nice to have nice tight stuff where it doesn't hang below the frame. For instance, this one the oil feed line comes out of the oil tank, makes a hard turn to the back and then loops all the way around up to the oil pump to feed oil. It's just shoddy looking workmanship. Whoever built this bike wasn't taking their time, they just want to get it done or whatever the case may be.

We're going to remove this rear exhaust pipe while the oil is draining out of the tank to show you one of the pitfalls the oil lines have to bypass on a Sportster motor and that is the rear-drive sprocket. Which is right here behind the cover where your kick arm comes through. We're going to loosen this because one of your oil lines or a couple of them feed down there, real close to this sprocket and if anything can ruin an oil line's life quicker is being rubbed by a rotating chain at high speed.

Come on. We'd loosened this up earlier. There's a nice tight fit you won't have to worry about exhaust leaks. Ok now we are gonna just slide this off hopefully with... Nice and clean, you'll notice the brake pedal and the brake cable line all fit inside here and it's all hanging all over a place but if we move this forward and take this cover out if we can get it out or rotate it around, you'll notice that one of the oil lines feeds down through here. This is your return line from the pump, it's about a fingers width away from the sprocket and the chain.

The factory originally came with a little clip that would hold that oil line and tight, you wouldn't have to worry about it walking out. In fact, you could actually see here close that at one time this oil line walked out, touched the chain freight a little bit of the steel braiding and then it was tucked back in where it is now. Before we put this all back together and give it back to the customer what we're going to do is we're going to take this and tie it in with a couple of cable ties to make sure it doesn't come out, rub the chain or the chain rub it, and we're going to clean up and probably tie it up under here too.

Okay, looks like our oil tank is done, one or two drops. If you just bought this motorcycle or you've had it for a while and you're worried about contaminants it wouldn't hurt to pull the filler plug and take a long screwdriver like this and stick it down in the tank and slide it along the floor of the tank as close as the drain plug as you can get, and pull it out and see what you got on the end.

This has a little bit of sludge. Not much just a little. If you were that much worried about it you could take a little bit of kerosene or diesel, put your plug back in, take your feed line off and put some diesel in there and shake the bike back and forth, then let it drain out. That'll take that sludge with it and move it all out of the picture then you put fresh oil back in. I would reroute the feed oil line and it'd be good to go with a nice clean sense of mind that there're no contaminants in that tank any longer.

If it's your first oil change since you bought the motorcycle, I would take the return line off the pump where it comes to the tank and I would put three quarts in, get the motorcycle started and pump the first half a quart back into a separate container because all the oil that's already in the vehicle or in the motor is contaminated, it's used. If you're making an oil change, you put the fresh oil in the tank, you want fresh oil throughout the motor so the half a quart that's in the motor circulating you would dump it into a clean container.

You could look at it and see where it is. When the oil returning to that container starts to be clear like fresh oil, you just turn it off, top off the tank, close it up and you're done. That can go for Sportsters, Panheads, Shovelheads everything. You just want clean oil, because clean oil means long life. Okay, we'll stick this in. God, can you get a close-up of this? Wow, that thing has been beat up. Anyway, we'll find a replacement for it before we give it back.

Last thing to do for an oil change is put fresh oil in. Here we're going to use some Valvoline racing oil 60 weight because it's summertime. I've always followed the first rule of thumb. Is the first frost, for you guys other than California you can change to 50 weight because it's colder. In the summertime, you use 60 weight, better protection. We're going to put some 60 weight in here. Just dump it in. In fact, just dump it up like this and it'll finish all by itself. You need a funnel? After you put the first quart in, just slice the bottom of the oil bottle off, and you have an instant funnel. It'll work for this, for your primary, whatever.

If by some unknown reason you want to use some slightly used oil which you should never do, you can strain that oil through a paper towel in a funnel. Stay. If you use the funnel, just take a paper towel line in there, pour your oil and you're going very slowly, but if there're any contaminants, you think you may have gotten something in there, you'll capture it before it goes back in the tank. Oil is cheap. You're going to use like $3 or $4 bucks a bottle. You should never use anything but fresh oil, period.

When you change the oil in the primary-- I was growing up on the East Coast where it gets cold in the winter which is like 10 months out of the year. Guys who ride Sportsters, the oil in your primary chaincase is shared by your transmission gears. You'd like to have a little heavier weight gear oil for the transmission gear so they don't damage themselves but the heavy oil in a cold climate when it's like 30 degrees and you still want to ride, God knows why, the clutch would dag because the oil has to warm up enough for the clutch to separate the plates when you pull the clutch in to shift gears.

We ran ATF in the winter months back there in Sportsters. ATF is running automatic transmissions behind V8 automobile engines and truck engines and it's got the viscosity, and it's got the molecules in to protect the gears, it's also got the lightweight that'll let the clutch discs separate when you come to alight. It warms up quickly, you don't have to worry about-- Back then for like a 30-degree weather, if you're out riding, it would take you 16 to 17 miles of running about 40 or 50 miles an hour for your oil to come up to even working temperature.

Working temperature for oil is 160 degrees right around there. At 160 degrees you start to cook off any water vapor that has contaminated the oil. How did water vapor get into your oil? Through your vent system. Sportsters have two vents; they have the vent line that goes back to your tank above your oil level. It also has this tube that comes out of your generator opening in your timing chest. I've seen bikes in the wintertime sitting at idle maybe 10, 15 miles on the engine puffing water vapor out of the vent tubes. That's the easy way to get rid of the water vapor, by heating the oil.

Heating the oil is only accomplished by running the engine down the road, and ATF works, but as soon as summer would come, say March, April we would take the ATF out and put the heavyweight back in. A lot of guys ran ATF all year round it was just personal preference to them, but it's just something to consider when you're in a cold climate a Sportster is your only means of transportation to work, to school, to the old lady's house, whatever.

All right, the last item to be adjusted on this is the rear chain. It's pretty much the same as the front chain. We're going to adjust it, so it has about a half-inch up and down play between both sprockets; transmission sprocket to rear wheel sprocket. We're going to rotate it around, find out where the tightest spot is, and we're going to adjust it to the tightest spot. See, you'd almost make that thing hit the drain plug now. Right there, that's the tightest spot. Doesn't need to go far. Okay, to adjust the chain you got to remove the rear wheel rearward, makes sense. You'd want to loosen your axle just slightly. You want to loosen-- This is the backing plate support bolt that actually anchors the backing plate so when you hit the brakes the whole back plate and drum don't want to rotate. You need to have that loose slightly, so that slides with the axle.

You put an Allen bolt in to adjust the axle. How are you going to get Allen bolt wrench in the Allen bolt. We'll refer back to our trusty pliers and we'll just have to rotate it back a little bit. Still looking tight. You don't want the axle too loose. If you have it too loose, the frame will spread if somebody didn't make the wheel spacers perfect. I'm assuming that the way this thing looks sometimes is that they're not perfect. Regardless, we can move it back.

You want to move it back the same amount on both sides. Wrong wrench.

Okay, it's tightened up a little bit. I'm going to go a little more. Okay, that's nice, right there, but we're going to double-check. There we are. We're back. The other thing you do before you tighten the axle up is you're going to spin the wheel in direction of travel two or three times and you're going to come back and look at your sprocket, how the sprocket falls in between the side plates of the chain.

For the sprockets to be aligned as you spin this, the sprocket will be equal distance from the inside links. This one is a little bit closer to the inside links, closer to the wheel. You can adjust that out but we got proper tension. This thing's a little bit on a weird side, we're going to roll with this. We come back reaching here, tighten our axle.

Okay, one of the tricks one rigid frame brakes is, you'd like to tighten your backing plate bolt and that centers the brake shoes. What we're going to do is we're going to sit here, we're going to spin the rear wheel and hit the brakes. That'll automatically center those shoes in the drum. I like to do it two or three times. All right, you get it down tight to the last third time, you hold the brakes on which means the brake shoes have been centered in the drum, you reach in here and tighten.

Okay, once you get a semi-snug, you can come in and tighten it the rest of the way.

It still has a loose spot but where it's tight it's perfect. We're done. We go back. There's no locknut on this adjuster. There's one on the other side. We're going to go over and lock the locknut down and we're d

Related Products